Top Tips for Effective Vending Machine Inventory Tracking Strategies?

In today's fast-paced world, vending machine inventory tracking is crucial. Many businesses rely on vending machines for additional profits. However, effective management of inventory can be challenging. A lack of proper tracking can lead to overstocking or stockouts. This not only affects sales but also customer satisfaction.

Imagine a scenario where a popular snack runs out during a busy day. Customers may feel disappointed and seek alternatives. Inventory tracking helps prevent such situations. Knowing which items sell best allows operators to keep popular products available. Tracking also aids in identifying slow-moving items that can be replaced.

Despite advancements in technology, many companies struggle with implementation. Some may rely on manual tracking methods that are prone to errors. This can lead to wasted resources and lost revenue. Reflecting on these challenges highlights the need for better practices. Improving vending machine inventory tracking should be a priority for operators to boost efficiency and enhance customer experience.

Understanding the Importance of Vending Machine Inventory Tracking

Effective vending machine inventory tracking is crucial. It affects sales, customer satisfaction, and overall profits. Studies show that nearly 30% of vending machines fail because of poor inventory management. Without accurate tracking, operators can’t meet customer demand.

Regularly monitoring stock levels helps in identifying trends. For example, one report indicated that products with higher sales rates can run out quickly. If not tracked, operators may miss opportunities for restocking in time. Advanced tracking systems allow operators to analyze sales data and recognize peak periods. This data is essential for optimizing inventory and maximizing revenue.

Vending machine operators should also consider human error. Manual tracking can lead to mistakes, affecting profit margins. An automated inventory system reduces these errors and enhances efficiency. While many operators still rely on traditional methods, the risks are high. Embracing technology may seem daunting, but it can ultimately improve operations and customer satisfaction. Ignoring this aspect could mean losses in both sales and customer loyalty.

Choosing the Right Inventory Management System for Vending Machines

When selecting the right inventory management system for vending machines, clarity is essential. A great system should automate stock tracking. Research shows that poorly managed inventories can lead to a 20% loss in potential profits. This highlights the need for real-time data access, allowing operators to respond swiftly.

Consider the user interface. A complicated system can deter employees from using it effectively. Industry reports indicate that 70% of operators who rarely check their inventory usage miss out on optimizing their restocking schedules. Simplicity helps in compliance and daily operations; staff need clear, actionable insights.

Real-time analytics play a crucial role. Systems should provide data on sales patterns. In fact, 45% of businesses using advanced analytics have seen a significant improvement in inventory turnover. Yet, many rely solely on manual entries, risking inaccuracies. Regular training for employees is vital. Overlooking this can lead to misconceptions about stock levels and unmet customer demands.

Top Tips for Effective Vending Machine Inventory Tracking Strategies

| Strategy | Description | Benefits | Tools/Systems |

|---|---|---|---|

| Automated Inventory System | Utilize software to track inventory levels in real-time. | Improves accuracy and reduces manual errors. | VendSoft, Cantaloupe, SupplyOne |

| Regular Stock Audits | Perform weekly checks on stock levels and expired products. | Ensures fresh products and optimal stock availability. | Manual tracking sheets, Inventory scanning tools |

| Sales Data Analysis | Analyze sales data to predict inventory needs based on trends. | Helps identify popular items and adjust stock accordingly. | Excel, Google Analytics |

| Communication with Operators | Establish a direct line of communication for inventory management. | Improves restocking efficiency and reduces downtime. | Messaging apps, Collaboration tools |

| Cloud-Based Management | Use cloud solutions for inventory tracking accessible from anywhere. | Allows remote management and real-time updates. | Quickbooks, Square |

Implementing Regular Inventory Audits for Optimal Performance

Regular inventory audits are crucial for vending machine success. They help identify discrepancies between expected and actual stock levels. Conducting these audits on a weekly or monthly basis can uncover patterns in product sales. This information guides restocking efforts and ensures popular items are always available. Frequent checks also prevent expired or outdated products from remaining in the machine.

During audits, it is essential to document findings accurately. Using tracking software can enhance this process. However, relying solely on technology can lead to oversights. Taking manual notes while inspecting the machines provides an additional layer of detail. Maintaining a checklist can help ensure every item is counted and assessed.

Sometimes, audits reveal unexpected results, like low sales of certain items. This prompts reflection on product selection and pricing. If specific items consistently underperform, it may be time to rethink inventory strategy. Overall, regular inventory audits promote optimal performance and sales in vending machine operations.

Utilizing Technology for Real-Time Inventory Monitoring

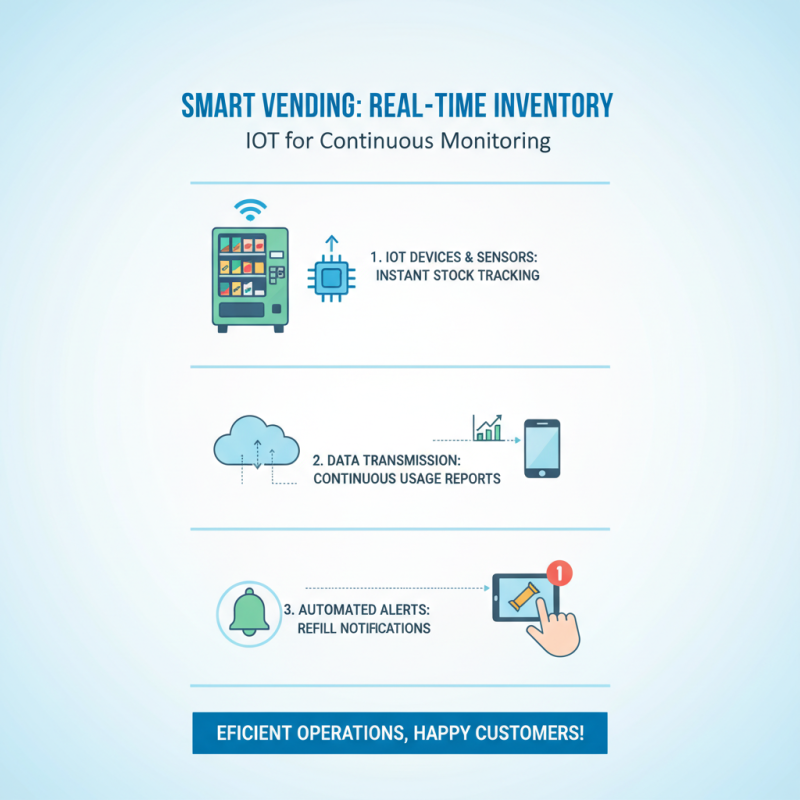

In today's fast-paced environment, real-time inventory monitoring is essential for successful vending operations. Using technology like IoT devices, operators can track stock levels continuously. These sensors report data on product usage instantly. When a snack runs low, the system alerts the operator immediately.

These systems are not without challenges. Internet connectivity issues can disrupt communication. Moreover, initial setup costs for advanced monitoring systems can be high. Smaller vending businesses might struggle with this investment. Yet, the advantage of preventing stockouts outweighs these concerns. Operators can adjust inventory based on real-time data, ensuring popular items are always available.

Another aspect to consider is data analysis. Collecting data is one thing, but making sense of it is key. Trends can emerge from consumer preferences. Operators might notice that certain locations sell different products better. Recognizing these patterns allows for smarter restocking decisions. Without careful analysis, valuable insights can be lost. Investing in training can help teams understand technology better, leading to a more responsive inventory management system.

Analyzing Sales Data to Refine Inventory Selection and Strategy

Analyzing sales data is crucial for refining inventory selection in vending machines. By closely examining which products sell and when, operators can make informed decisions. Reports suggest that inventory turnover can increase by 30% when driven by data analysis. This shift results in fewer expired items and better customer satisfaction.

Real-time data can reveal trends that may not be immediately obvious. For example, sales might spike during specific times, like lunch hours. However, some operators fail to adjust inventory based on this insight. They may stock too many snacks and miss opportunities for healthier choices. Integrating flexible inventory strategies allows for adaptability.

Still, data misuse can lead to poor choices. Relying solely on historical data without context might ignore evolving consumer preferences. Reports indicate that 25% of vending operators do not adjust their stock based on seasonal changes. Not recognizing this can lead to stale inventory and lost revenue, highlighting the need for continuous reflection and strategy adjustment.

Vending Machine Sales Data Analysis

This chart illustrates the sales performance of various product categories in a vending machine over a month. The data showcases the importance of selecting the right inventory based on sales trends.

Related Posts

-

What is the Best Vending Machine Solution for Businesses Looking for Vending Machines

-

Top 10 Benefits of Choosing Refurbished Vending Machines for Your Business

-

Unlocking Profit: How Businesses Looking for Vending Machines Can Optimize Their Space for Success

-

Top 5 Vending Machine Businesses To Watch in 2025 for Your Sales Strategy

-

2025 Top Digital Vending Machine Innovations for Smart Retail Spaces

-

Unlocking Profits: How Ice Vending Machines are Revolutionizing the Beverage Industry